Issue No. 11 - July/August 2000 |

|

|||

|

Back Issues: |

Inside: Features The Work Behind the Scenes Cheese and Good Health London Marathon Success Only 10% of Emmental is Swiss 'Paint a Picture' competition winner Cheese Focus: Recipe: Tools of the Trade:

|

|||

|

Welcome to the 11th Issue of 'The Teddington and Kew Cheese Wire', an issue full of cheesy news and information. Also, a summer greeting to our latest Restaurant and Hotel customers who may be receiving our newsletter for the first time. We invite you to discover Chris Duckett's Caerphilly, one of the most respected British farmhouse cheeses. Also in this issue we pay a visit to a couple of our suppliers and find out how hard they are working to produce some of your favourite cheeses. Now that summer is here, an exciting cheeseboard is the easy answer to your entertaining problems. Half a dozen cheeses together with some crunchy biscuits or bread and a selection of pickles and fruit (try pears, figs, fresh dates and big slices of watermelon) takes care of the food. All you have to do is open some wine and help yourself to your favourite cheeses. |

||||

|

|

||||

|

|

||||

|

Above: In the Comté cellar we tasted "plugs" from 3 different cheeses, at 6 months, 12 months and 17 months of maturity. As the cheese ages its paste becomes denser as the moisture gradually evaporates, and the flavour intensifies. Anyone who has tasted a really mature hard cheese will know that it can be almost "crunchy".

Above: Many cheeses are sent to our own maturing rooms when semi-ripe. Care for the final maturation is then passed onto our head cheesemongers, Orlando Gibson and Ed Williams.

Above: Petit Langres are never turned during ripening which produces a sunken top.

|

THE WORK BEHIND THE SCENES |

|||

|

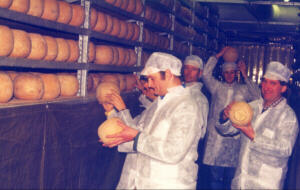

Regular customers and readers of this newsletter will know how much we value our suppliers. In fact they are often mentioned by name on our cheese cards and on our web site. A great many of our cheeses are bought directly from the farms where they are made, so when we place an order we usually get a chance to discuss the cheese with the person who makes it. This helps us learn how to bring out the best in the cheese as well as equipping us to answer your questions. As more and more people discover the superior flavour of traditionally-made food, cheese is a great example of how small-scale production can create something that not only tastes far better than its mass- produced counterpart but is also about as simple and unprocessed as food can get. This simplicity and integrity is very much in evidence when we visit the farms where our cheeses are made. At Greenacres farm in East Sussex, Kevin Blunt milks his own goats which have grazed in his own fields before his wife Alison adds the rennet and a dash of salt to make their award-winning Golden Cross cheese. Despite the short list of ingredients, the Blunts produce a cheese of exceptional texture and flavour thanks to the quality of their milk and their skills as cheesemakers. Having visited them at work and seen for ourselves the discipline and judgment that goes into making the cheese, we treat it with the utmost respect when it arrives at our shops to be matured. When it comes to excitement and sheer variety, French cheeses are second to none, and this is based not only on centuries of cheesemaking tradition but also on an instinctive feel for good ingredients which is at the core of the French palate. We recently visited one of our French cheese suppliers who buys cheese from small farms all over France and matures them in his cellars near Lille. The array of cheeses in his premises reflects the diversity of the French regions; with separate cellars devoted to Comté, Mimolette, Epoisses and an astonishing range of goats cheeses, all of which are inspected daily as no two cheeses reach maturity in the same way or at the same time. Humidity and temperature are strictly monitored, and traditionalists insist that the bacterial cultures resident in a really well-seasoned cellar have a unique part to play in the flavour of these famous cheeses. While our own maturing rooms may not yet be 100 years old, we do try to see as many cheeses as we can in their 'native' environment and to learn whatever we can about the process that makes a farmhouse cheese taste so special. We always aim to offer you the best in terms of variety and flavour, and to keep learning so as to do justice to the hard work and talent of the cheese makers whose produce we all enjoy so much. |

||||

|

Cheese and Good Health |

||||

|

Customers ask us every day how we are able to resist the temptation to eat our cheese and not pile on the pounds. The answer is that we can't resist them. In fact, we have to taste each and every cheese to be sure they are ready and at their best. There are few better and more sociable meals than a good cheeseboard with biscuits or bread and even after spending years as cheesemongers this never fails to excite us. Tony Parkes says 'As all good nutritionists will tell you, it's all about getting the balance right. Our bodies need energy, vitamins and minerals and these are found not only in fruit, vegetables, pulses and other 'healthy' foodstuffs but also in those we consider naughty - chocolate, cakes and, of course, cheese. A good balance of all these foods together with regular excercise allows us to enjoy our cheeses.' Toby Gibson continued 'Finding excercise which suits you is important. I run and also cycle into work every day - it is not only good for me but it is also quicker, cheaper and less stressful than using a car. In fact, in our Kew office, three out of four staff have abandoned their cars in favour of cycling.' |

London Marathon Success Three cheesemongers, Orlando Gibson, Tony Parkes and Toby Gibson from The Teddington Cheese completed the London marathon this year. Orlando Gibson said after the race 'I was overwhelmed by the amount of genuine support from the spectators on every part of the route. Despite total exhaustion, blisters and an inability to talk coherently for an hour or so after the race, I had a great day and can't wait to do it all again next year!! ' |

|||

| back

to top

|

||||

|

Caerphilly This stalwart of Welsh cheeses has been made since the middle of the 19th Century and originated in small farms close to the town of the same name. It rapidly grew in popularity with the Welsh miners. It was already known that cheese absorbs the toxic substances inhaled in the mines, and cheddar was a popular choice. Caerphilly however became an instant hit, its fresher flavour and softer texture making it more palatable 'down the pit'. Early in the 20th Century, with the advent of steam trains, Welsh farmers found that they could export their milk directly rather than making it into cheese. This was more profitable. The gap was filled by cheddar makers across the Bristol Channel in Somerset. They found that Caerphilly had a much shorter maturing time of a week to ten days. There was therefore no lag between the start of the season and cheese production. During World War II, production of Caerphilly and all other cheeses except cheddar, was restricted to that which was intended for personal consumption. This hit Welsh cheese makers particularly hard and the recovery after the war took several decades. Our Caerphilly is made in Wedmore, Somerset by the Ducketts. It is made to a family recipe that has been handed down through three generations. Chris Duckett still uses traditional equipment such as the double Victorian cheese presses. He uses milk from specific local farms situated on the peaty soils of Tealham and Tadham Moor. The whole cheese is approximately 4kg in weight, and is made in a four hour process. The rind is formed by brining for 24 hours after pressing, and is then dried and whitened with rice flour. The cheese is ready to eat within a week of being made. Caerphilly is a moist, crumbly cheese with a pale-coloured paste. It has a slightly sour but buttery flavour and a sharp, but not overpowering smell. Made from unpasteurised cows' milk using vegetarian rennet, it is a full fat cheese with a fat content of 48%. £1.22 per 100g (£1.38 per quarter) at The Teddington Cheese and The Kew Cheese |

Cheese Sablé Biscuits These light cheese biscuits make a great accompaniment to pre-dinner drinks. You can use all kinds of cheese but strong hard cheeses will give the best flavour. Ingredients: 1.Rub butter into sifted flour.

|

|||

|

Only

10% of Emmental is Swiss!

|

||||

|

Swiss cheeses are made using raw milk from small farms which take their milk twice a day to their local cheesemaker. The traditional methods and recipes combined with the excellent milk ensures cheeses of the highest quality. Today, only 10% of Emmental is actually made in Switzerland and unfortunately, much of the non-Swiss Emmental falls short of the original version. We have been working closely with the 'Swiss Cheese Dairy' to help raise awareness of traditional Swiss cheeses, of which there are now over 450 varieties. At a recent show (BBC Get Cooking Show at Olympia, London) we exhibited several of these including the creamy Fribourgeois, the hard Sbrinz (used like Parmesan) and Appenzeller, Tête de Moine and Tilsiter. You will have another chance to taste and buy these fine cheeses at the BBC Good Food show at the NEC, Birmingham between the 29th November and the 3rd December. It would be great to see some of our mail-order customers at the show. |

|

|||

|

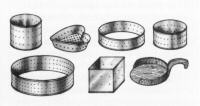

CHEESE

MOULDS When presented with the rectangular blocks of cheese in supermarkets, we tend to forget what a whole cheese looks like. Real cheese comes in a wonderful range of shapes and sizes, from pyramids and logs to 130kg Emmentals. For most cheeses the shape is determined by the mould into which the curds are pressed. The first evidence of cheese moulds comes from Columella in the 1st Century AD, who wrote of curdled milk being transferred to rush or osier baskets. As soon as the curds became firm, weights were placed on the filled baskets to force out the whey. Osier baskets were soon to be used in Great Britain and still used by some soft cheese makers. The problems with this type of mould is that they are very difficult to keep completely clean. For this reason most contemporary moulds are made from wood, metal or plastic. Although the great variety of cheese moulds makes it difficult to give a general description, they all share one major feature. That is, sufficient drainage to allow the whey to escape, leaving just the curds. For this reason, some cheese makers have found that colanders make the ideal cheese mould. For example, Ticklemore is moulded between two Woolworths colanders. In most cases the curds are placed into cloth-lined moulds and then pressed. Obviously the degree of pressing depends on the type of cheese required. Hard, close-textured cheeses such as Cantal are pressed 3 or 4 times to remove as much liquid as possible, whereas soft goats' cheeses are just lightly pressed once. Many of the soft disc shaped cheeses like Ardrahan are pressed in cylinder shapes, then cut into discs at a later stage. |

||||

| BACK TO TOP | ||||

| All articles © www.teddingtoncheese.co.uk | ||||